| |

| |

|

|

|

|

|

|

|

|

| |

Guldner AK 1959

This page is dedicated my

Guldner AK 1959 model. I am the second owner, former owner from the

tractor was new is Rasmus Rasmussen from Utsira west of Haugesund

(Norway). Rasmussen traded the tractor in for a new Hurlimann

tractor from Åse Landbruk in

2000.

It's an old tractor, and it's not

looking like new anymore. And I didn't know if the engine would run

when I brought it. But after a few attempt it started with a nice sound

and loots of black smoke. Almost everything is working like it

should. (except the dynamo, lights and some other simple things) It runs

at amazing 20Km/h in high speed gear and approximate 1.5Km/h in low

speed gear. It has six gears forward and two reverse. The biggest problem

is some rust, especially in the fenders. (the rest of the chassis is of

aluminium) Have been working with the tractor sins 2001 (VERY slowly!) to

get it in a better condition. My hope is to get it in good working order,

not in a "better than new" state. |

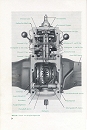

| From

the handbook. |

|

|

| |

|

|

| |

|

| |

|

| |

|

| |

|

|

| |

|

| |

|

| |

|

|

| |

|

| |

|

| |

|

|

|

|

REBUILDING: Summer 2001. Here the

tractor body is painted and the time have come for putting it all together

again. Will take some time sins a lot of parts still are in the condition

like when I got it. The colour is not original but

as close as I could get from the original paint. This is my first tractor

"restoration" Have been working some with motorbikes and cars but

not a huge job as this, so I had to learn it the hard way. A lot of

mistakes have been done, and I have learnt a lot.... |

|

Picture at left:

February 2003 have not been working on it for over a year,

hope to start over again in a short time! Well I was wrong in at this moment

I was also working an a far newer MF235 witch got most of my time,

but that's another story. It should go long over a year before I

concentrated on the Guldner again. At this time some major problems

had occurred. The hydraulics pump and the steering worm . First the

hydraulics: The oil seal on the pump hydraulic piston was clearly in

a bad shape. It fell apart when I dismantled the unit. Happily a

local company "Bauer Nielsen" in Haugesund could help. I measured

the piston and they found a oil seal in their assortment range witch

should fit.

|

|

Fall 2004: Picture at left, old

and new oil seal. I now understand why the lift capacity was so

low.... |

|

|

Pictures at left: The hydraulics unit

from behind and the new oil seal on the piston. It wasn't the

easiest task to install the hydraulics unit on the

piston. But at least it now seems to have the right compression. |

|

|

Next big problem was the steering.

You could turn the steering wheel almost one turn before the wheels

started moving. By dismantling the steering worm

it was clearly that sometime in the past there had been three ball

bearings (marked by arrows in the pictures) I was not able to get

new bearing from any dealer so new ones had to be made. The

solution was a nylon stick and a friend with a lathe. Thanks to Knut

Aase who helped me with this problem. He made them in one day and

now the steering works perfectly. When this problem was overcome it

was time for putting it all together again. |

|

|

|

|

|

|

|

|

|

Summer 2005: In the last picture, row

above time had come to start the Guldner. All the parts wasn't

ready, the hood needs to be renovate, the fenders need some big rust

removing and the tree point hitch isn't ready. And a lot of details

need some more work to be ready. But the engine was ready, the

steering and breaks work so... big was the disappointment when the

diesel pump (picture right) didn't deliver fuel at all! A closer

look stated that the pump had sized. I was able to get it in working

order again but the engine would just run on full speed or not at

all. The regulator worked okay so it must be the pump. What ever I

did, it didn't help. Luckily my neighbour Kåre

Grind had a Kramer KB180 witch was "kaput". The Diesel pump made by

Bosch was the same, even the type number was the same. |

|

|

So, out with the original pump

and in with the "new" one. The tractor is still hard to start if its

cold in the weather but ones started it runs like it should have

done nothing else. |

|

|

|

|

|

|

|

|

Nov. 2005: At least its moving on its

own power. Big parts like the hood and fenders have to wait

until next summer. This winter I will try to get the details right,

replace damaged fasteners, new grease nipples, put the instruments

on etc. The nozzles have to overhauled and hopefully the hydraulics

will work. Installing the three point hitch, so on. One minor

problem is a "hole" in one of the engine top covers. (picture at

right) Have no idea how this happened, the no. 1 cylinder is

"leaking" throe it, but I thing that should be easily fixed. So

summer 2006, then I think it should be complete. |

|

|

|

| |

|

|

|

|

|

|

Last

updated Nov 2005 |

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Some

technical information |

|

Description |

Data |

| Engine

type |

two

cylinder diesel, 4- stroke, |

| Displacement |

885

ccm |

| Output |

13

Hp |

| RPM |

2300

rpm |

| Fuel

capacity |

19

litre |

| Gears |

ZF,

3 x 2 forward, 1 x 2 reverse |

| PTO |

540

rpm / ride independent |

| Electric |

12V |

|

|

|

|

The manuals |

|

| |

|

The former owner Rasmus Rasmussen is

a man who take care of his stuff. With the tractor came the original

manuals that followed it from new.

That contains user manual in

Norwegian and German language and a manual for the hydraulics

in Norwegian. Her is a few samples of the German manual.

I have scanned the German manual, you

can download it here. PS: It's 68 pages saved as compressed

jpg pictures in a ZIP file, totally 4.6Mb

The other manuals will be scanned

later. |

|

|

| |

|

|

|

| |

|

|

|

|

|

|

| |

|

To

download the zip file: right click on the download pic at left and

choose "Save Target as" or just click on the picture! |

|

| |

Note:

the original format is A5, the scans are similar to A4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|